With the continuing reduction in the cost of solar photovoltaic (PV) generation systems, their deployment in industrial situations is becoming increasingly viable.

As with any investment the devil is in the detail and a number of considerations need to be considered when determining viability. This is to ensure that business cases are built on good engineering principals and have integrity. A valid overall economic and technical assessment is required to ensure that PV arrays are optimised to ensure maximum economic return. In New Zealand unsubsidised feed in tariffs (FIT) mean that PV arrays need to be ‘right sized’ to maximise self-use. This requires the analysis of the complex interplay between tariff structures, load profile and seasonal variations in solar insolation. An outline of key factors is provided below:

1. Understanding load profile

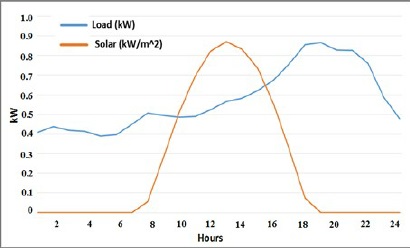

Ideally half hourly readings, available from smart meters, are a good source of data. Data with a resolution of greater than an hour e.g. averaged from monthly energy bills, is not ideal as excessive averaging tends to overestimate self-consumption, which is the key factor we try and optimise. For example, we could specify a system to generate 100kWh of PV generation per day to match a daily load of 100kWh. But if the load is biased in the afternoon, we would end up falling short in terms of self-consumption in the morning and producing surplus low return energy for grid injection in the afternoon. Hourly data provides a much more accurate estimate of self-consumption and provides an opportunity to tune the orientation angles of solar arrays to provide best yield to match the load profile.

Figure 1: Solar gain vs load requirement offset

2. Understanding the solar resource

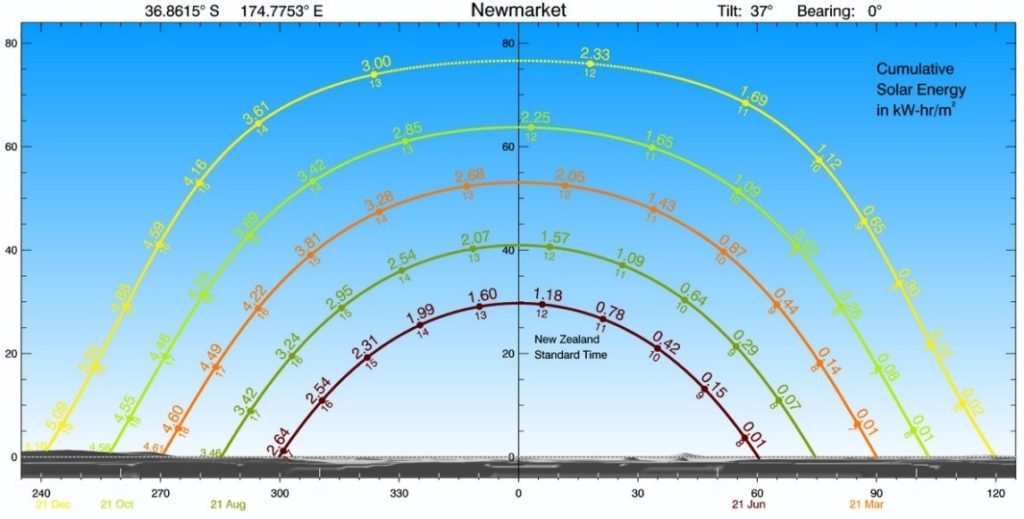

Generally this can be sourced from the National Climate Database for the nearest weather station to the site. At least ten years of data should be analysed including insolation levels, clearness index and temperature to construct a climate profile for the site. Alternatively NASA satellite data can be used to make an estimation.

Figure 2: NIWA Solarview calculator

3. Modelling

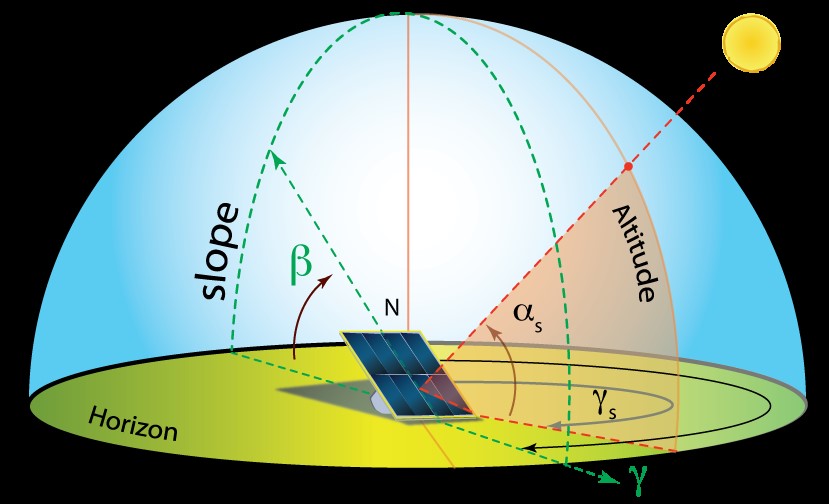

Required to establish the optimal configuration of the array in terms of size and angle orientation (tilt and azimuth). This is presented as a desktop study for pre-feasibility i.e. to establish whether the project is viable and whether it is worth going to the next step, a full feasibility study. This study would involve a site survey and a closer evaluation of site features that could impact on the output of the system, for example, shading due to topographical features or vegetation.

Figure 3: Solar panel tilt and azimuth example – Credit: Jeffrey R. S. Brownson

Neo’s depth of industrial electrical engineering knowledge means that we are extremely well placed to successfully integrate PV into industrial facilities. We understand industrial plant infrastructure, processes, load diversity and energy use and therefore the nuances involved in specifying and designing an industrial PV project. Our extensive experience in industrial processes enables opportunities for demand side management to be investigated to achieve closer alignment with the PV generation profile and therefore maximise value.

Neo has undertaken several PV projects in the industrial sector. Our modelling expertise when integrated with our experience integrating different energy sources (solar, diesel generation and grid supply) helps strike a balance between all elements described to ensure project value is maximised.

The time for industrial PV systems is now; well designed systems can contribute economic value along with helping energy consumers play their part in achieving a more sustainable future. If you would like to discuss how you could reduce your carbon footprint and enjoy the benefits of industrial PV generation, please get in touch.

Richie Murray

Principal Engineer

d: +64 9 365 9734 | t: +64 9 365 9720 | m: +64 27 501 0499 | e: richie.murray@neo.co.nz