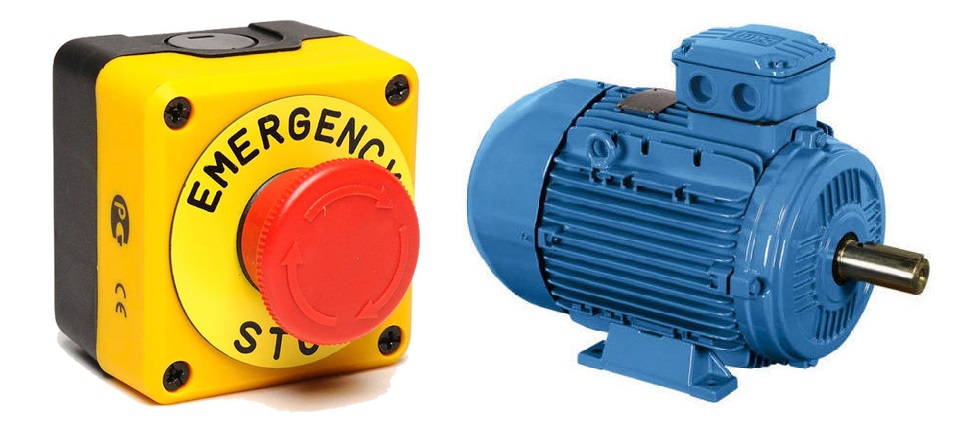

As electrical designers of industrial plant we are often subjected to differing views on the regulatory requirements for emergency stopping of electric motors. One specific, and often reoccurring question relevant to us in our day-to-day work is this:

“When emergency stopping of motors connected to semi-conductor devices e.g. variable speed drives or soft starters, do you need an isolating device in the supply OR, for example, can the Safe Torque Off (STO) feature of these devices be solely used to provide this functionality?”

The STO option is generally far simpler and cheaper to implement when compared with the installation of additional switching devices, such as contactors, to achieve this. But is this compliant? Our view on the regulatory requirements of these options is as follows.

The current legislated requirements for electrical installations in both Australia and New Zealand are known as the Wiring Rules and defined by standard AS/NZS3000:2007. The underlying principal of this standard is to ensure safety of persons, livestock, and property against dangers associated with electrical installations. These standards are split into two parts, namely:

Part 1 – Provides the uniform essential elements that constitute the minimum regulatory requirements. Basically, Part 1 defines high-level outcomes without prescription; and

Part 2 – Provides installation practices (prescription) that achieve certainty of compliance with Part 1.

Our interpretation of these standards are:

a) All electrical installations must comply with Part 1.

b) The simplest route to compliance is to adhere to the requirements of Part 2 (1.9.4).

c) To comply with Part 2, all motors must be provided with an emergency switching device capable of emergency stopping (4.13.1.1 b). This shall be in the form of an isolating device that interrupts the main supply (2.3.2.2, 2.3.5.1, & 2.3.5.2). This therefore excludes the sole use of a semi-conductor device to provide the emergency stopping functionality (2.3.5.2). Some notes to this:

- i) The motor’s main isolator could be used to meet this requirement (2.3.5.2. a). If so, it must be located at an accessible and identifiable place where the danger may occur (2.3.5.3) and labelled accordingly (2.3.5.4). However, these devices are typically located in remote switchboards which contravene these requirements.

- ii) A suitably rated local isolator could be used to meet this requirement (2.3.5.2. a), providing it is located and labelled as such (2.3.5.3 & 2.3.5.4). This is a common and relatively cheap form of compliance, particularly for small motors (although not recommended on the output cables of a VSD).

- iii) The contactors of direct-on-line (DOL) started motors, or line-side contactors installed external to VSDs and soft-starters, which are controlled by remote emergency stop button(s) could also be used to meet this requirement (2.3.5.2 b).

- iv) The Standards do not prohibit the use of the STO function of a semi-conductor device being used in conjunction with a circuit which physically isolates the supply to a motor e.g. line-side contactors.

d) The use of a semi-conductor device for functional control switching of a motor is acceptable (2.3.7.1). Functional switching however cannot be used for safety switching.

e) If the installation does not meet the requirements of Part 2 then it could still be deemed compliant providing, amongst other things, a) The principals of Part 1 are satisfied; and b) the degree of safety provided is not less than that provided by complying with Part 2. (1.9.4). If this route is chosen, then the departures from Part 2 need to be documented (1.9.4.3) and acknowledged by both the designer and the owner (1.9.4.2).

Therefore, if using the STO of a semiconductor device alone (i.e. without contactors to physically break the supply) to provide emergency switching, our belief is that it is only compliant with the regulations by the use of Part 1 and a specific design installation solution. Compliance to this is onerous in terms of design compliance and sign-off. I am equally unsure what level of documentation and detail would be required to satisfy this.

Practically, we have seen motors installed on sites both with and without emergency stop functionality which fully isolates the supply. For those sites that have semi-conductor devices using the STO input for the emergency stop, or do not have emergency stops at all, the expectation (ultimately by Worksafe, EWRB etc. if required) is that documentation exists to satisfy the regulatory requirements of Part 1.

Bottom-line for me, if we’re talking about someone’s life, I want the best probability available that the motor will stop and be physically isolated in an emergency. The closest way to ensure this is by completely removing power to the device instantaneously. Despite assurances from the suppliers of semi-conductor devices, an STO alone simply won’t cut it for me!

*******

AS/NZS3000:2007 References

Part 1 – 1.9.4 Compliance by specific design and installation.

Clause 1.9.4.1 Use of a Part 1 design, 2nd paragraph

“Electrical installations or portions of non-domestic installations that do not meet Part 2 of this standard, may use a specific design and installation method as detailed below.

- Satisfy the fundamental principals of Part 1

- Will result in a degree of safety from physical injury, fire and electric shock not less than that which, in other circumstances, would be achieved by compliance with the particular requirements of this standard”

- satisfy the other requirements of this Standard as detailed in this Clause…

Clause 1.9.4.2 Acknowledgement by the owner or operator of the installation

“Any departures from Part 2 of this Standard must be formally acknowledged by the owner or operator of the installation”

Part 2 – 4.13 Motors

Clause 4.13.1.1 Switching device, 1st paragraph

“Every motor shall be provided with a switching device capable of performing the following functions:

(b) Emergency stopping, in accordance with Clause 2.3.5”.

Part 2 – 2.3 Control of Electrical Installation

Section 2.3.2 Common requirements

- Clause 2.3.2.2 Devices for Installation

“Devices for isolation shall effectively isolate all active supply conductors from the circuit. A semi-conductor (solid-state) device shall not be used for isolation purposes”.

Section 2.3.5 Emergency switching including emergency stopping

- Clause 2.3.5.1 General, 1st paragraph

“Means shall be provided for emergency switching of any part of an electrical installation where it may be necessary to control the supply to remove an unexpected danger.

Where a risk of electric shock is involved, the emergency switching device shall be an isolating device”.

- Clause 2.3.5.2 Emergency switching devices, 1st paragraph

“Means for emergency switching shall consist of:

(a) a single switching device directly interrupting the incoming supply; or

(b) a combination of several items of electrical equipment operated by one single action resulting in the removal of the hazard by interrupting the appropriate supply’.

Section 2.3.7 Functional (control) switching

- Clauses 2.3.7.1 General, 1st paragraph

“Functional switching may be used where switching of electrical equipment, or part of an electrical installation, is required for operational control only and not for safety reasons. NOTE: Functional switching devices may be switches, semi-conductor (solid-state) devices, or contactors.”

Nigel Stevenson

Managing Director – CMENGNZ (Electrical)

d: +64 9 365 9730 | t: +64 9 365 9720 | m: +64 27 433 0772 | e: nigel.stevenson@neo.co.nz