To combat ongoing clogging problems at one of their major pump stations within Tokoroa, the South Waikato District Council undertook the installation of an inline macerator.

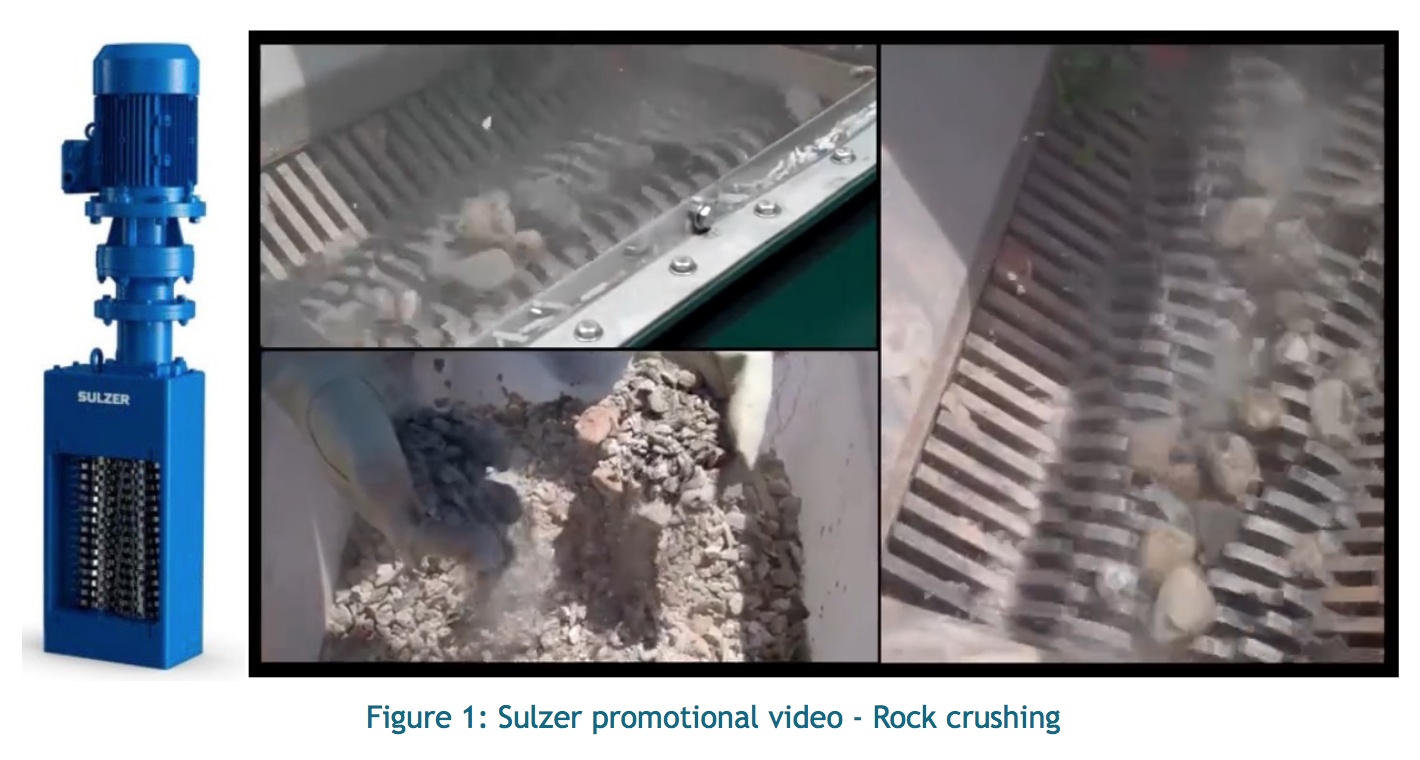

The macerator replaces a traditional bar screen installed within the pump station’s inlet channel, but was needing to be cleared and maintained regularly by operators. These units are designed to macerate everything that passes through them, and are so strong they can even crush rocks. By ensuring that all particles that pass through are macerated accordingly, the pumps remain unclogged as these smaller particles can then be pumped through the station easily.

This has meant that macerators are perfect for completing the required job. The problem however, is that due to their power they also pose a significant health and safety risk for anyone that is near while they’re in operation. To solve this risk, Neo worked with MTL to design a safety system that utilised both mechanical and electrical protection systems.

Before any safety system can be designed, you first need to know what level of protection is required. To do this, Neo organised and facilitated a machinery risk assessment (MRA) workshop. This workshop included representatives from the entire project team, including designers, operators, maintenance and management. By working through the entire life-cycle of the macerator and following the requirements of AS/NZS 4024:2019, it was determined that the safety system required a Category 3 Performance Level D rating.

To implement this, Neo designed a verified safety system which incorporated multiple features including:

- – Safety rated equipment – Safety relays, contactors, buttons

- – Local E-stop button – Manual removal of power by operators

- – Proximity switches on all access grates – Automatic removal of power if access hatches are opened that would expose access to the macerator.

- – Proximity switch on the macerator installed – Automatic removal of power if the macerator is removed from its support housing.

The final design and installation has ensured a safe and modern solution. Neo was proud to be part of a project and team who were proactive in ensuring others’ safety, and continuing to improve the safety of operational and maintenance staff working on this site.