New Zealand’s Health and Safety in Employment Act 1992 requires employers to take practical steps to ensure the safety of everyone in the vicinity of switchgear. This includes protecting individuals from one of the major hazards associated with switchgear faults – arc flash. In this blog, we will discuss the importance of arc flash audits and updates for maintaining a safe working environment and preventing damage to your equipment.

What is an arc flash?

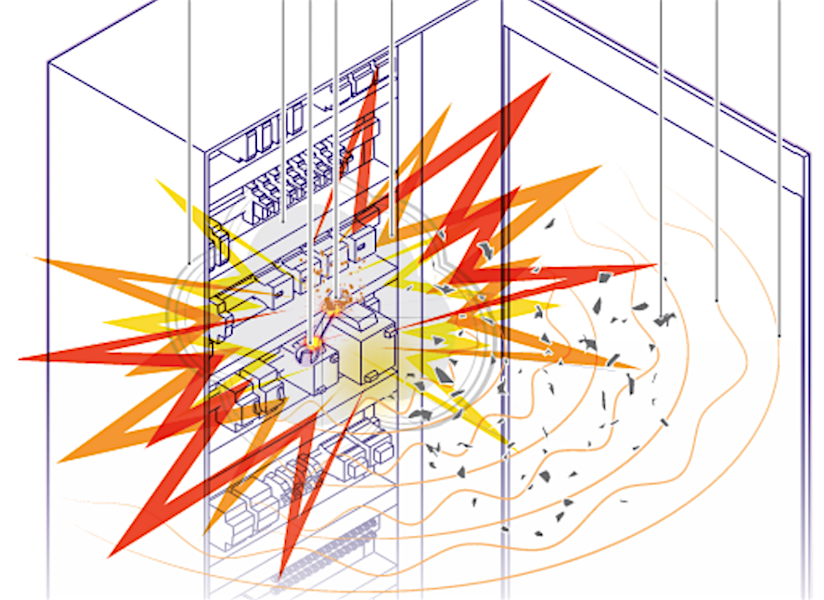

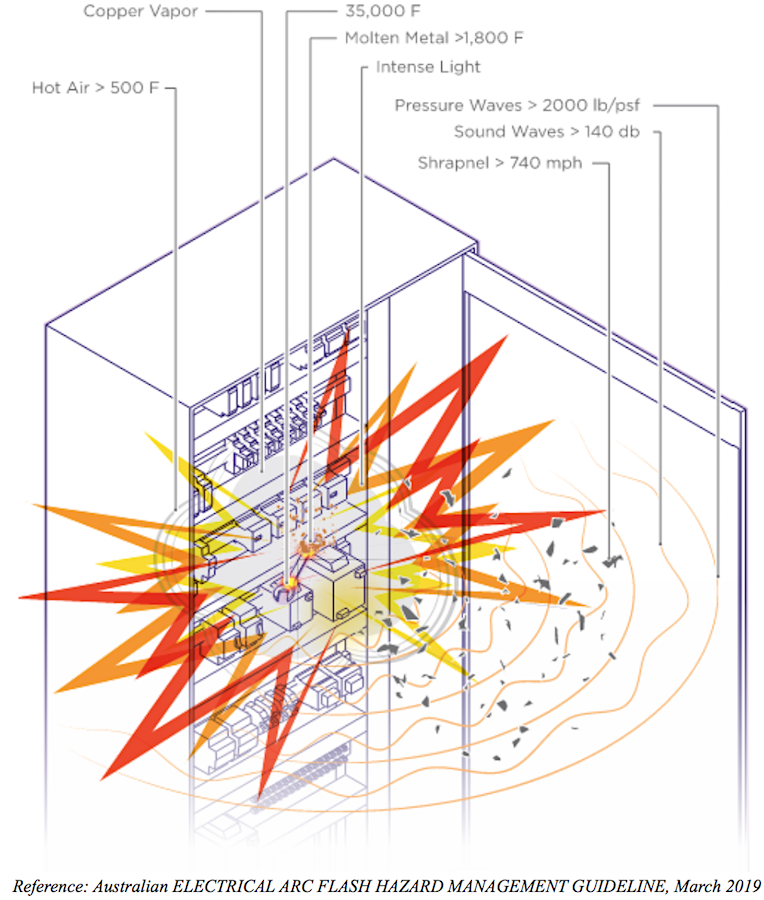

An arc flash is a hazardous electrical event that occurs when an electric current flows through an air gap between two conductive objects, resulting in an Arc discharge. This discharge can release intense heat, light and gases, leading to an Arc blast that can cause severe injury, or even death.

Why are arc flash audits necessary?

- – Legal obligations: Under the Health and Safety in Employment Act 1992, employers must take practical steps to safeguard their own employees, contractors’ employees, and members of the public. Failure to comply with these regulations can result in fines, prosecution, or even imprisonment.

- – Protecting personnel: Arc flash events are rare but extreme and can cause significant harm to personnel. Audits can help to identify and mitigate potential hazards, including specifying personal protective equipment (PPE) requirements, which can reduce the risk or severity of injury.

- – Protecting equipment: Arc flash events can also damage equipment, leading to costly repairs and downtime. Audits can help to identify vulnerabilities in equipment design and installation and suggest solutions such as addition of detection/protection componentry or mechanical hardware to mitigate the risk of damage.

What is Involved in an ARC Flash Audit?

An arc flash audit involves a comprehensive assessment of your switchboard’s safety. This includes identifying any potential hazards, assessing the level of risk, and developing solutions to mitigate those risks. Some of the components of an arc flash audit include:

- – Incident Energy Analysis: Established standards IEEE 1584 and NFPA 70E provide requirements and guidance with calculating the incident energy produced during an arc flash event. This analysis provides a baseline to determine the level of PPE required to protect personnel.

- – Solutions: Based on the audit, solutions can be proposed that range from defining PPE requirements, labelling, protection settings, addition of detection/protection componentry, mechanical hardware, or a combination of any or all of these.

To protect your employees, clients, and equipment, an arc flash audit is a vital service to support compliant with the Health and Safety in Employment Act 1992. The arc flash report needs to be reviewed anytime changes are made which may affect the arc flash rating of any part of an installation and periodically e.g., every two years. Implementation of the solutions recommended in the audit can help reduce the risk of arc flash and mitigate the potential harm.

Don’t wait for an accident to happen, contact Neo to schedule your arc flash audit or click through to our arc flash audit service page for more information and to download our PDF service guide.