As regulatory demands within the water industry become more significant, many waters managers are finding that those dusty PC boxes and screens in the corner of the office / remote sites are becoming increasingly important. Not only is the data, and the reports they produce becoming of more interest, but the number of times that they fail, alarm, or cause problems with missing data, is increasing in frequency. To make matters worse, significant changes in the water industry are looming. A regulator has been signalled which will increasingly place a spotlight on these systems and their ability to demonstrate: compliance, stability, management of change and system security (see our publication Compliance data management for more information).

When upgrading a SCADA system, a problem clients often face is trying to get simple answers about how up to date the system is, and what needs to be done to improve its reliability. The responses are normally complex, and frustratingly different stakeholders (i.e. existing contractors / suppliers) will provide various views on what needs to be done, how long it will take, who needs to be involved and who can help. We can assist you to cut through all the jargon to explain the system in simple terms. We have also found our 9-layers of SCADA model really helps non-technical stakeholders understand the scale, complexity and interdependencies of a SCADA system (see our publication What’s in a SCADA for more information).

Upgrading a SCADA system is generally more costly and time consuming than many organisations allow for. Unfortunately, avoiding the issues won’t make them go away. Whilst applying short term patches can often delay the need for a major upgrade, ultimately the longer you wait to address fundamental issues the harder the hill to climb will be when it is finally undertaken. This is because an increasing amount of deteriorating existing equipment cannot be reused (even temporarily during a migration) due to incompatibility with newer technology. This is where the development of a plan is vital to manage the migration. As reusing equipment can cause rework and disrupt the most efficient upgrade path for the system.

An important point to note is, you are not alone!

At Neo we have deep industry experience with many water authorities around New Zealand who are battling the same problems. We have helped them with the assessment, design, specification, and delivery of new SCADA, telemetry and control systems. There is a growing realisation that No.8 wire fixes are no longer the best answer and a more structured approach needs to be embarked on when upgrading a SCADA system.

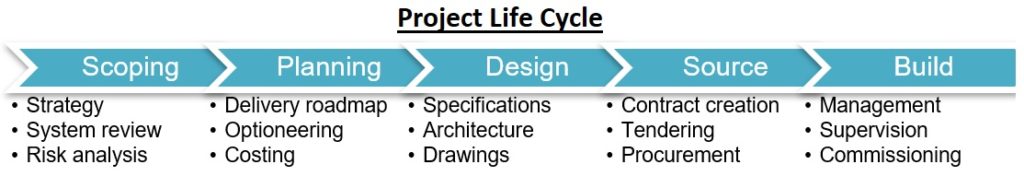

Neo can assist in demystifying the problems, risks and develop options in ways that can help you understand how to break down your issues and get on the right implementation path. In addition to our deep experience in design and implementation support we also understand planning, business case development, procurement requirements, system management, risk and opportunity identification. We also have a successful track history in supporting the ultimate handover to operations. Our experience has shown us that the upfront scoping and planning stages are essential to put the project on the right path.

No matter where you are in your project life cycle, Neo has developed strategies to assist you to deliver the best results.

To join the growing number of water authorities taking advantage of Neo’s independent expertise in this area, or if you would like a sounding board to discuss projects you already have underway, then please get in touch.

Richie Murray

General Manager Business Development

d: +64 9 365 9734 | t: +64 9 365 9720 | m: +64 27 501 0499 | e: richie.murray@neo.co.nz